When you hear the term “electronic enclosures,” it might sound a bit technical. But don’t worry! This guide will break it down for you in simple terms.

Whether you’re a DIY hobbyist, a product designer, or someone who just wants to understand what protects your electronics, this article will walk you through what electronic enclosures are, why they matter, and the different types available in 2025.

Table of Contents

What Are Electronic Enclosures?

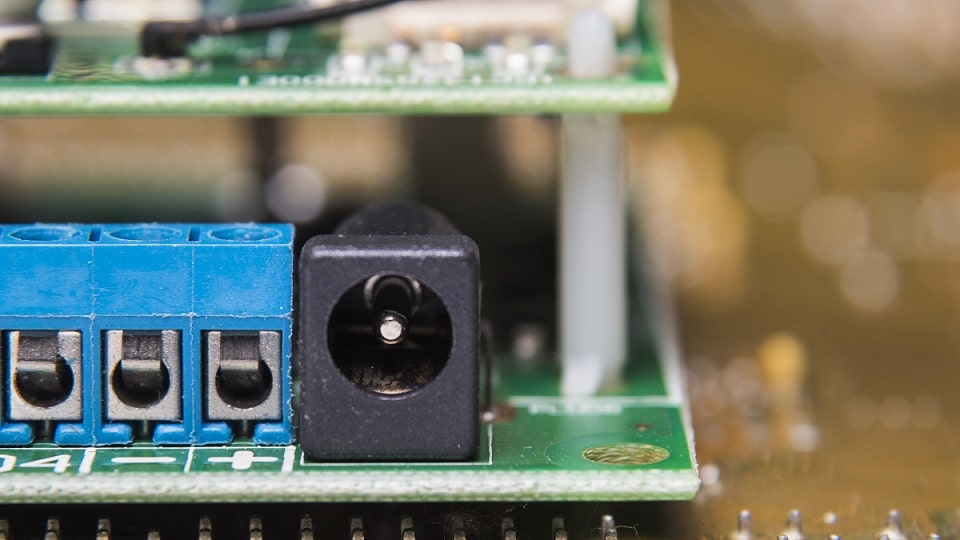

Electronic enclosures are boxes or protective shells designed to house electronic components. They shield sensitive circuits from environmental elements like dust, water, extreme temperatures, or impact.

For example, think about your smartphone case or the control box of a washing machine — these are forms of electronic enclosures. Without them, devices wouldn’t last long or work reliably.

In 2025, as electronics become more compact, connected, and placed in more demanding environments (like smart outdoor devices and industrial sensors), the need for specialized enclosures has grown rapidly.

Why Do We Need Electronic Enclosures?

Still wondering why these boxes are a big deal? Here’s why they’re more important than ever:

- Environmental Protection: Modern devices operate in harsh places — factories, vehicles, outdoors — where dust, water, and chemicals can damage them.

- Safety for Users: Proper enclosures protect users from electrical shocks and fire hazards.

- Better Performance: Enclosures help manage heat and prevent interference from other devices, which improves reliability.

- Compliance: Many industries now follow strict international standards (like IP ratings and NEMA ratings) that require specific types of enclosures.

Different Types of Electronic Enclosures

There are many types of electronic enclosures, each suited for different applications. Let’s explore some of the most common ones.

1. Plastic Enclosures

These are some of the most common electronic enclosures you’ll see in homes and offices. Used in gadgets like remotes, power adapters, and consumer electronics, they’re easy to mold and mass-produce.

Advantages:

- Lightweight and cost-effective

- Non-conductive, reducing the risk of electrical shorts

- Easy to customize with different colors and shapes

Disadvantages:

- Less durable against strong impacts

- Not ideal for high-heat environments

- Lower resistance to chemicals and UV rays

🔍 2025 Tip: New biodegradable and recycled plastic enclosures are emerging for eco-conscious consumers.

2. Metal Enclosures

Made from aluminum, stainless steel, or galvanized steel, metal enclosures are strong, rugged, and ideal for environments where durability and heat management are essential.

Advantages:

- Excellent protection against physical damage

- Great at shielding devices from electromagnetic interference (EMI)

- Superior heat dissipation

Disadvantages:

- Heavier and more expensive than plastic

- May require grounding to prevent electric shock

- Can corrode if not coated or treated properly

🧠 2025 Insight: Many industries are adopting powder-coated aluminum enclosures for better corrosion resistance without adding weight.

3. Die-Cast Enclosures

Die-cast enclosures are a type of metal enclosure made by injecting molten metal into a mold. These are popular in industries needing both strength and precision.

Advantages:

- High mechanical strength and durability

- Ideal for rugged outdoor or industrial use

- Excellent EMI and RFI shielding

Disadvantages:

- Heavier than molded plastic options

- Costlier due to complex manufacturing

- Less flexibility in customization

🛠 Pro Tip: In 2025, many companies now offer 3D-printed die-cast prototypes for faster product development.

4. Fiberglass Enclosures

These are reinforced with glass fibers, making them resistant to chemicals, corrosion, and extreme weather conditions. Fiberglass enclosures are commonly used in marine, oil, and power applications.

Advantages:

- Non-corrosive and chemical-resistant

- Lightweight yet tough

- Handles both high and low temperatures well

Disadvantages:

- Brittle under very heavy impact

- Slightly more expensive than plastic

- Limited size availability

🌱 2025 Trend: Fiberglass enclosures are now available with UV-resistant coatings to increase their life span in sunny environments.

5. Polycarbonate Enclosures

Polycarbonate is a high-strength plastic that offers excellent impact resistance and clarity. These enclosures are great when you need to see inside or need added toughness.

Advantages:

- Stronger than most plastics; shatterproof

- Available in transparent options for visual inspection

- UV-resistant versions are ideal for outdoor use

Disadvantages:

- Slightly more costly than regular plastics

- Can scratch over time, especially the clear versions

🔎 2025 Update: Anti-scratch polycarbonate enclosures are being widely adopted in medical and tech wearables industries.

6. Waterproof Enclosures

These are specifically engineered to protect electronics from water ingress — a must for outdoor and marine applications.

Advantages:

- IP-rated for protection against water, dust, and corrosion

- Great for outdoor, marine, and industrial settings

- Some models include built-in seals and pressure equalizers

Disadvantages:

- Typically heavier and more expensive

- Require proper sealing during installation to maintain waterproof rating

📡 2025 Update: Waterproof enclosures with smart ventilation (to release pressure without letting in moisture) are becoming standard for IoT devices.

Choosing the Right Electronic Enclosure

Selecting the right enclosure is more than just picking a box. It’s about matching the right material and features with the job the enclosure needs to perform. Ask yourself:

- Will the device be used indoors or outdoors?

- Does it need to be waterproof or chemical resistant?

- How much heat does it generate?

- Will it be exposed to drops, shocks, or vibration?

- Do you need clear visibility or EMI shielding?

Always consider the IP rating or NEMA rating when choosing enclosures for tough environments.

Installation & Maintenance Tips

Installing an enclosure the right way ensures it lasts longer and protects better. Here are modern best practices:

- Use Certified Seals: Choose gaskets that meet your application’s temperature and pressure needs.

- Avoid Over-Tightening Screws: This can damage seals or crack plastic enclosures.

- Label Clearly: In 2025, smart labels with QR codes are being used for quick scanning of maintenance records.

- Routine Inspection: Especially for outdoor or high-impact enclosures, check every 6–12 months for wear or seal degradation.

Final Thoughts

In today’s connected world, electronic enclosures are more important than ever. From smartphones to outdoor sensors and industrial robots, every device needs a secure, efficient, and safe housing.

Understanding the strengths and weaknesses of each type of enclosure helps you make better decisions — whether you’re building a product, fixing one, or just trying to learn.

As technology advances in 2025, newer materials and smarter enclosure designs are emerging, making devices more durable, compact, and efficient than ever before.

So next time you see a sleek box around your tech, remember: that little case is doing a big job.